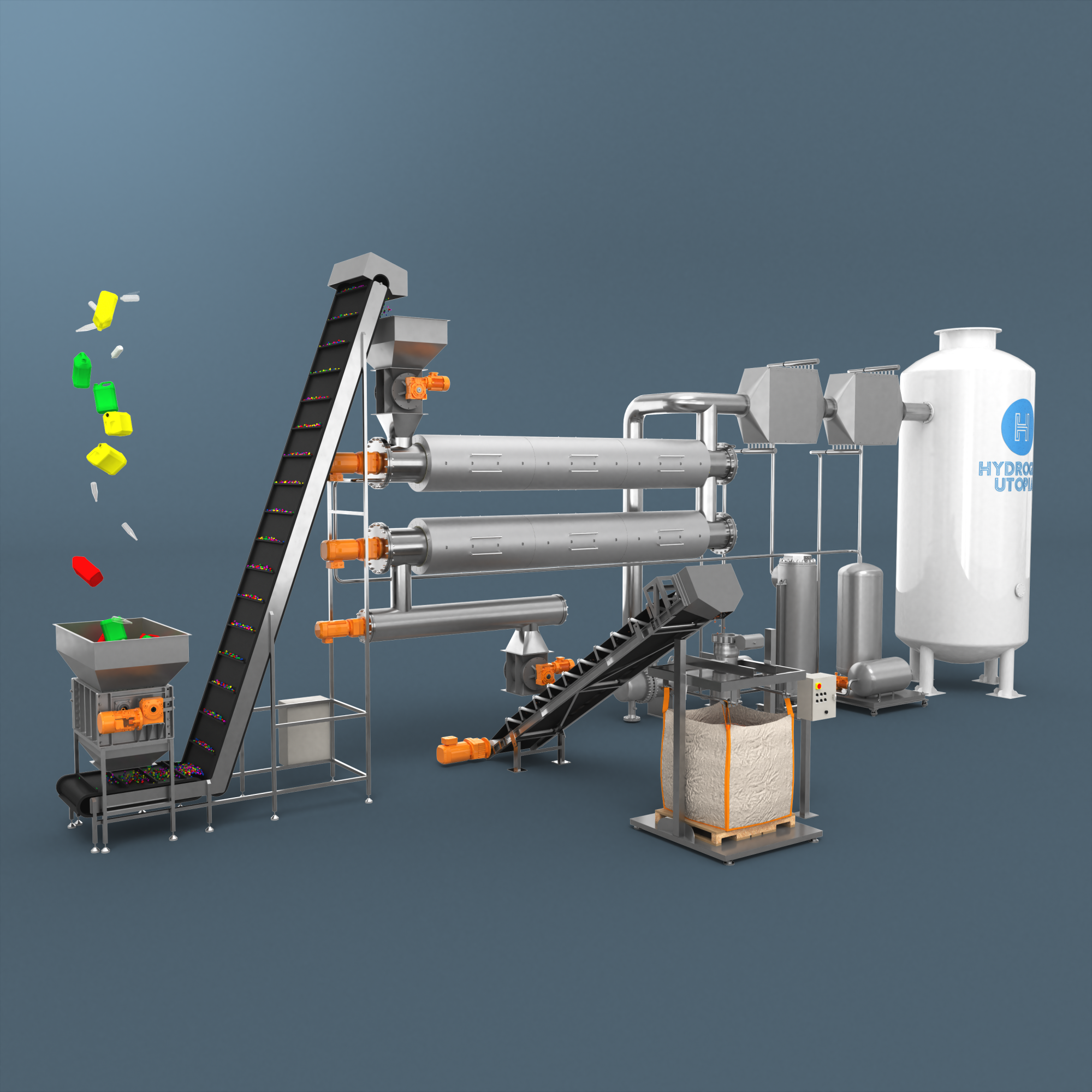

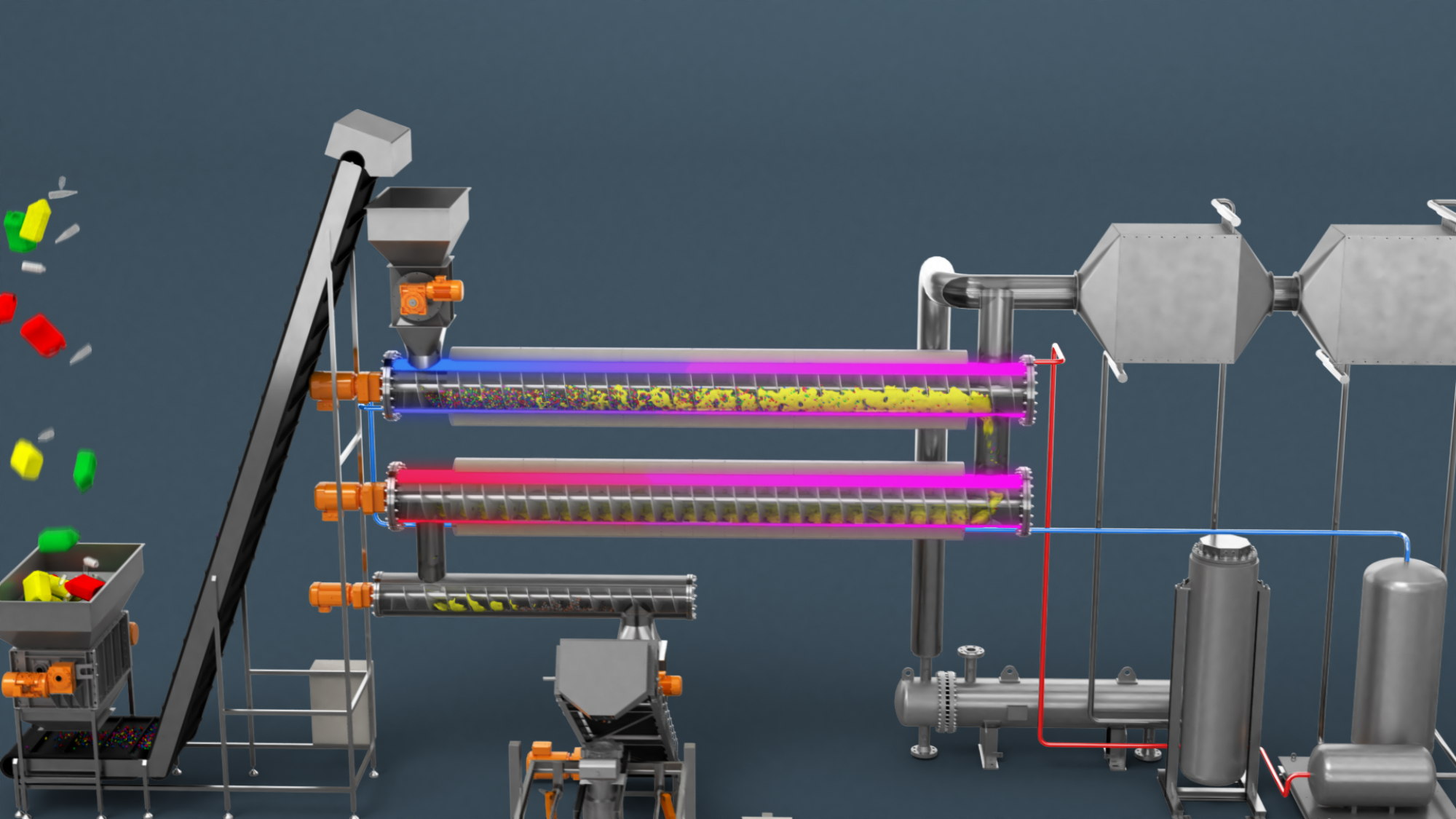

Continuous Pyrolysis Furnaces

Electron provides various sizes of continuous type pyrolysis furnaces for applications such as:

- Thermal cleaning of polluted soil.

- Thermal recycling of industrial waste.

- Thermal recycling from plastic to oil.

- Mercury and precious metals recycling.

Depending on the application and the products being processed the furnaces are equipped with thermal oxidizers (incinerators), gas quenches using air atomizing cooling techniques, fabric filters, activated carbon or urea injection, wet scrubbers, or dry bed absorbers. Just to ensure an appropriate flue gas treatment before emitting gasses into the atmosphere and/or to make sure the precious metals are reclaimed completely.

Instead of using a typical rotary kiln furnace, the Electron design features a static furnace system with integrated paddle/screw type conveyor system.

Features

Complete polymer/plastic/oil/mercury removal or recycling in a continuous process. |

Multiple paddle pyrolysis conveyors with independent temperature and Oxygen control. |

Separate incinerator with Oxygen control to ensure complete combustion of all hydrocarbons. |

Integrated heat recovery devices for high energy efficiency of the furnace system. |

Automatic process control to monitor the pyrolysis process including automatic throughput adjustment. |

Capacity up to 10 tons per hour in a single system. |

Electron offers environmentally and operator friendly pyrolysis furnace systems for thermal cleaning and/or thermal recycling. The unique design and salient features and a long list of satisfied customers makes it an easy decision to ask for a quotation.

Our method

At Electron, we are pleased to discuss and explain our many value adding technologies and to think along with our customers. We have extensive experience in designing and manufacturing custom electric heating elements and systems, furnace accessories and insulation materials. Our employees will be happy to advise you on the best solution for your application.

More information?

Please contact us if you are interested to learn more about any features of our continuous pyrolysis equipment and we would be pleased to discuss and explain our many value adding technologies within this specialist area.